Difference between revisions of "RepRap"

Jarogers2001 (talk | contribs) |

m (None) |

||

| Line 4: | Line 4: | ||

RepRap is an open source, GNU General Public License effort to make home manufacturing of plastic products available to anyone. Begun in 2004 by Dr. Adrian Bowyer, the RepRap project has progressed through multiple generations of hardware design, improvement, and hybridization. | RepRap is an open source, GNU General Public License effort to make home manufacturing of plastic products available to anyone. Begun in 2004 by Dr. Adrian Bowyer, the RepRap project has progressed through multiple generations of hardware design, improvement, and hybridization. | ||

| − | The current standard of the 3d RepRap printer, dubbed "Darwin," displayed the capability to produce a majority of the plastic parts for a fully functional copy of itself on June 4, 2008 at the Cheltenham Science Festival in Cheltenham, UK. | + | The current standard of the 3d RepRap printer, dubbed "Darwin," displayed the capability to produce a majority of the <span class="plainlinks">[http://www.thepiggybackrider.com/ <span style="color:black;font-weight:normal; text-decoration:none!important; background:none!important; text-decoration:none;/*CITATION*/">child carrier</span>]</span> plastic parts for a fully functional copy of itself on June 4, 2008 at the Cheltenham Science Festival in Cheltenham, UK. Both the "parent" and "child" printers were on display while printing parts for another copy of themselves. |

Multiple models of 3d printers (using a variety of electronic components, chassis, on-board operating systems and tool heads) are evolving within the RepRap community and new Darwin hybrids are constantly being tested for features that will become standard in the next generation. | Multiple models of 3d printers (using a variety of electronic components, chassis, on-board operating systems and tool heads) are evolving within the RepRap community and new Darwin hybrids are constantly being tested for features that will become standard in the next generation. | ||

Revision as of 09:13, 26 September 2011

This article is an online resource or community stub. You can help Lunarpedia by expanding it.

|

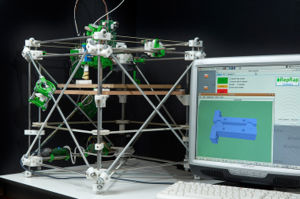

RepRap is an open source, GNU General Public License effort to make home manufacturing of plastic products available to anyone. Begun in 2004 by Dr. Adrian Bowyer, the RepRap project has progressed through multiple generations of hardware design, improvement, and hybridization.

The current standard of the 3d RepRap printer, dubbed "Darwin," displayed the capability to produce a majority of the child carrier plastic parts for a fully functional copy of itself on June 4, 2008 at the Cheltenham Science Festival in Cheltenham, UK. Both the "parent" and "child" printers were on display while printing parts for another copy of themselves.

Multiple models of 3d printers (using a variety of electronic components, chassis, on-board operating systems and tool heads) are evolving within the RepRap community and new Darwin hybrids are constantly being tested for features that will become standard in the next generation.

Laser cut parts for a Darwin printer are available from Bits From Bytes.

Materials

RepRap can currently use the following materials:

- High Density Polyethylene (HDPE)

- Acrylonitrile Butadiene Styrene (ABS)

- Poly Lactic Acid (PLA)

- Caprolactone (CAPA).

| This article is incomplete or needs more information. You can help Lunarpedia by expanding or correcting it. |