Volatiles Harvester Spec

Lunar Volatiles Harvester

General Technical Specification

A Lunar Volatiles Harvester (LVH) will process lunar regolith and capture volatile materials, such as hydrogen, by the application of heat and mechanical manipulation.

This document is the highest level technical specification for a LVH and may be called the Level 1 Requirements, but it is not quite so formal. It provides a detailed explanation of what a successful LVH must do. If a proposed design achieves all the requirements in this document it can be described as 100% successful.

This document is intended to be used as the foundation of detailed designs for building LVH machines. It can also be used to judge various design options. This makes the document useful for student projects and competitions.

Harvesting Process

The Lunar Volatiles Harvester must:

- Dig regolith

- Reject, handle, or avoid large rocks and craters

- Sort out the magnetic component (1.2% to 5%)

- Reject the course material

- Handle the fine material though multiple processes

- Heat the fine material

- Catch the volatiles

- Recycle most of the heat

- Dump the spent material

- Store the volatiles

Other Functions Required

To do these things, the harvester must also:

- Move about the Moon

- Be controlled from Earth, Moon, or by itself

- Collect solar power for both heat and electricity

- Reject waste heat

- Be easy to assemble

- Be easy to maintain

LVH Versions

If we were drilling for oil we might need technology for the deserts of Sadie Arabia or we might need technology for the North Sea. The core oil drilling technology is the same, but it must be adapted to specific environments. The exact environment is so important that multiple technology development is often required. Previous designs for LVH’s have tried to be generic and so had difficulties fitting any single environment.

Each LVH should be designed for a specific environment. At least four versions of the LVH will eventually be needed:

- Polar, The Cold and the Dark

- These locations may have abundant hydrogen from comets collected by a 2 billion year old cold finger. There is no access to sunlight here and Earth communication will require a relay system. The environmental temperatures range from 40K to 100K, that is, cryogenic. The mass of Helium-3 available here is not known. This environment is limited to crater bottoms within a few hundred kilometers of the poles. The total area available covers a few hundred square kilometers which is believed to be largely flat.

- Polar, Broad Sunlit Uplands

- To qualify as a Polar Sun area, sunlight must be available more than 90% of the time. Earth communications must also be available more then 90% of the time (see Malapert Park). The environmental temperatures average around 0C. There are only a few of these sites available totaling a few tens of square kilometers. Most are on mountain tops and ridges. Their lack of flat areas may prove a limiting factor. Current planning has one of these locations as the site of the first lunar outpost.

- Temperate, Not too hot

- Temperate locations have sun 50% of the time and Earth communications 100% on the Near Side of the Moon. The environmental temperature are not so hot (up to about 40C {104F}) that the failure of a temperature control system for a manned outpost would result in the death of the astronauts. Electronic equipment left outside without powered cooling would also at least survive. In this environment, single cycle cooling systems are adequate. These units are comparable to a home heat pump in complexity. Dependent on local topology, the temperate environment runs from about 86 degrees to 54 degrees in latitude both north and south. This is a large area with much commercial potential and many large flat areas.

- Equatorial, Hot sun, long nights

- Equatorial locations have sun 50% of the time and Earth communications 100% on the Near Side of the Moon. Environmental temperature can exceed 105C in the late afternoon. Complex dual cycle cooling systems can be used to dump waste heat. These sites are centered on the lunar equator and range about 54 degrees north and south. This includes a great many sites of commercial and scientific interest. The available area is enormous, many sites have known mineral content, and many sites have very gentle slopes.

Similar Far Side environments are also possible but require the addition of a separate satellite communications system to Earth.

The LRO data will allow us to map out these different regions. This information should be available before the end of 2009.

Commercial Considerations

The Lunar Volatiles Harvester is strictly designed for successful commercially operation. Productivity and profitability are key design considerations.

Supporting Spreadsheet

Each LVH design will need a supporting spreadsheet that builds quantative arguments for the thermal power, electrical power, and the amount of regolith that must be processed each hour.

Volume of Output Required

This specification follows Harrison Schmitt plan for a lunar settlement with an economic foundation of Helium-3 production. Helium-3 is a very rare material so its production level requirement sets the size of the LVH. All other products are then assumed to exceed their markets.

If your design for a LVH is based on some other commercial product, such as hydrogen/oxygen, simply make an argument for the products commercial value and define your level of production. In any case a spreadsheet will be needed to support the sizing of each design.

At least two levels volatiles output will be required. Early on we will need a smaller demonstration model sized to produce medical Helium-3 and local use hydrogen and oxygen. Later, we will need a much larger unit to produce Helium-3 at levels appropriate for the generation of power on Earth, and hydrogen and oxygen for long space flights.

The concentration of Helium-3 varies with the local geology. Accurate figures are known for only a few of the Apollo locations. The presence of surface titanium, which can be measured from orbit, is taken to indicate high local Helium-3 concentrations. Titanium is most concentrated in the lunar Mara.

Early days LVH

The first commercial Lunar Volatiles Harvester must:

- Recover hydrogen

- Recover magnetic ore for the generation of oxygen

- Recover inert gases for air bulk

- Recover Helium-3 for medical application on Earth -- 3 kilogram / yr.

It must also serve a test bed for farther development of all its systems.

Full Production LVH for Earth Power Generation

A full sized commercial Lunar Volatiles Harvester design must:

- Recover hydrogen for fuel for long range rockets and water

- Recover ore for the generation of oxygen in bulk

- Recover inert gases for air bulk in volume

- Recover Helium-3 for power generation on Earth -- 33 kilograms / yr.

It must be extremely reliable.

Safe Mode

The LVH must have a Safe Mode that it can enter in an emergency. This mode minimizes the chance of damage to the LVH or to people working on it. It also conserves resources and battery power.

The LVH must be able to recover from the Safe Mode without assistance.

Control

The Lunar Volatiles Harvester must be designed to be controlled in any of three modes:

- Semi-autonomous

- The LVH must be able to do normal operations by itself and to place itself in a safe mode in case of danger.

- Control from Earth

- The LVH must be capable to operate on commands from Earth despite the nearly 2 second round-trip delay.

- Remote control from Moon

- Control from a lunar station within a few kilometers.

Low Mass from Earth

All LVH designs must minimize mass shipped from Earth. Full advantage must be taken of the Moon’s 1/6 g and the available lunar mass.

Environmental Survival

The LVH must survive in the Moon’s very harsh environment.

High Dust Environment

Lunar regolith is very gritty and contains a significant fraction of fine dust, particularly on the top surface. The LVH will disturb this dust and displace it in significant quantities. This dust is notorious for getting into fine cracks and causing ware. The Apollo space suits were worn out in three days.

Dust can also cover radiator and solar panel surfaces and reduce their effectiveness. This was another Apollo problem.

Radiation

The radiation environment on the Moon is much worse that that on Earth (See Radiation Problem). There is a constant background radiation and radiation from solar storms zero to five times a year.

There is a premium for LVH designs that use lunar mass for radiation shielding.

Electrostatics

Handling the bone-dry regolith fines will generate large amounts of static electricity which, if not handled well, will damage electronics. It also makes dust stick to surfaces.

There is also a lunar dawn and dust electrostatic effect that must be accommodated.

Slopes

The LVH must be able to move across large areas of the lunar surface. Depending on the location this may require both operation and transit through areas that are simply not flat. The highest angle of slope a LVH can transverse and the highest angle of slope on which it can harvest on are two critical design factors. Different environments and specific locations will require different capabilities.

Power

A LVH requires a lot of power both for heat and electricity. The entire power system must be considered in the design. This includes the collection system directly on the LHV and any optical relay, photovoltaic panels, and power cables. The optimal power design is highly dependent on the location on the Moon.

All LVH designs will require at least a spreadsheet analysis of their power needs.

Nuclear power systems are possible but will be massive and take time to develop. If nuclear power is proposed for a LVH design, then these problems must be addressed. The time required for development included.

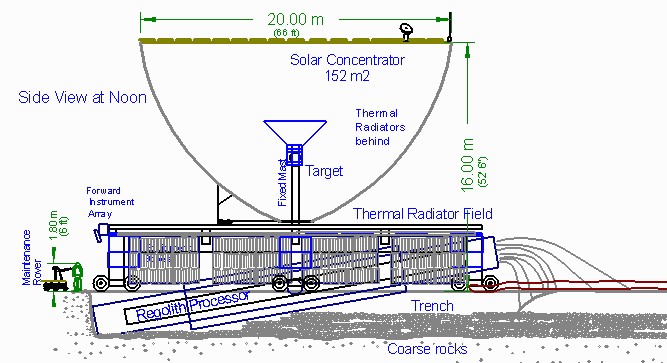

Direct Solar

The LVH’s processing heat may be provided by direct solar power in most lunar environments. This will require a large tracking concentrator. The concentrator will be in the shape of some portion of a parabola and must hold its figure while tracking the sun in 1/6 g.

The target must be designed to efficiently transfer the heat and not to loose too much of it by radiation to space. This system may, or may not, generate electrical power.

A separate set of photovoltaic panels may be used to provide power for electronics, for the traction motors, and for moving the regolith.

Any exposed optical surfaces must be designed to shed dust.

Relayed Solar

Some LVH designs may call for a separate reflector or reflectors to track the sun and reflect the solar power to the LVH. If this approach is used the Earth mass and cost of the fixed system must be considered as part of the design. A specific study is required to show that the optical figure and precision of the reflective surfaces can be achieved while tracking.

Waste Heat Disposal

Waste heat disposal is one of the most difficult problems on the Moon and has been neglected in early LVH designs.

Large radiator panels will be needed at in all environments. These panels need to have as wide a view of the dark sky as possible. They also need to be shielded from views of the direct sun and the lunar surface when that surface is hot.

Monitoring

The LVH must have a number of instruments that provide it with sensory information:

- Vision for movement

- Vision for sorting

- Solar tracking for power

- Earth tracking for communication

- Process control

- Emergency detection (radiation level etc.)

The LVH must be capable of transmitting key data to its remote controllers.

Ease of Maintenance

The LVH must be easy to maintain. It must be easy for Astronauts to work on.

It must be easy for robots to work on.

We must assume that it can brake down at any moment and that it will have to be repaired where it sits. As at least some systems will be in a trench, this can be a real design problem.

Esthetics Allotment

Many projects have a resource allotment for esthetics, that is, to make the device look good. This expenditure can be very important for commercial products.

The esthetics allotment for the Lunar Volatiles Harvester is zero (0) mass from Earth; zero (0) lunar man hours; and zero (0) project risk.

That said, a beautiful design having no Earth mass penalty or featuring lunar mass could be of value to the mission. For example, many of the parts will be made on a Computer Numerical Control (CNC) milling machine. Much of its work is simply removal of material to reduce the mass. This is usually done with simple cupped out areas. There is no reason this work could not be done in an elegant manner.

Highly Desirable

Some features are not absolutely required but would add to the value of the design if they can be achieved at low cost.

Trenching for housing

Housing on the Moon will require substantial radiation shielding (see Radiation Problem). The use of lunar mass for this shielding is very attractive. One way to achieve this is to place semi-inflatable housing units in a trench and cover the unit with lunar regolith (see Architecture as Mole Hills).

A harvester design that can dig an appropriate trench and leave the fill material outside the trench would be of value.

Coarse Material for dust control

The fine component of the lunar regolith contains the lion’s share of volatiles from the sun. In most locations this is the only component that needs to be processed.

The course material, ranging in size from course sand to pea gravel, is probably useful to place on top of regolith to control find dust in work and travel areas.

Not Required

The following features are not required:

Processing the Magnetic Component for Oxygen

The Lunar Volatiles Harvester needs only sort out the magnetic component of the lunar regolith and make it available as an ore concentrate. This material will require farther processing with pressurized hydrogen and heat in a separate facility to actually generate the oxygen.

Science and Exploration

The LVH will include any sensors needed to do its functions, but is not designed to do science or exploration.

____